Solutions

Fault Code Assignment and Management

Within the eXpress and Integrated Systems Diagnostic Design (ISDD) environment, the assigning and managing of the Fault Codes for the BIT throughout the design development of the Integrated Vehicle Health Management (IVHM) for any on-board embedded diagnostic or Production Floor ATE application is a rather simple and error-free integrated process. To perform this seamless capability, the ancillary eXpress Maintenance Module is required.

Before any Fault Codes are assigned, the objective would be to ensure that these Fault Codes contain much more diagnostic savvy than the trivial detection of an impending, or existing, loss of any operational function(s). To realize the potential of this advanced embedded diagnostic savvy, it would require that the Fault Codes additionally encapsulate diagnostic inferences of the Integrated System as exploited in the deployment or operation of the fielded design. This knowledge will then enable the integrating of “diagnostic conclusions” that are encapsulated in the reporting of the Fault Codes, ensuring the performance of accurate diagnostic resolution – where multiple diagnostic “levels” must be comprehensively “bridged”.

Therefore, the use of the eXpress Maintenance Module will be used to coordinated the assigning of the Fault Codes to the performance methods and requirements indigent to the sustainment paradigm. Let’s first examine how the eXpress Maintenance Module addresses our sustainment paradigm.

Although this same capability owns a companion interactive mechanism to also fully “sort, retire and manage” the disposition of updated or modified Fault Codes during the Design Development and Sustainment lifecycle(s) in an error-free and nearly immediate endeavor, let’s first examine how the eXpress Maintenance Module configures and assigns the Fault Codes to accommodate any complex sustainment paradigm.

The approach described below highlights some of the procedural steps to prepare the eXpress model for this additional purpose and benefit.

eXpress Maintenance Module Interoperability

The eXpress Maintenance Module is an advanced feature that facilitates the “bridging” the diagnostic inference “levels” for use in production environment with popular ATE or any comprehensive sustainment activity. It is able to leverage the vetted BIT test coverage and its interdependent diagnostic inference savvy as determined within eXpress, and then enable the (re)use of diagnostic conclusions gained from the reporting of BIT status data from or within the operational and sustainment activities. As the demand in industry continues to swell as it exploits the ROI from this unique “diagnostic inference bridging” capability, the eXpress Maintenance Module will continue to evolve to accommodate a myriad of advanced run-time diagnostic applications or highly specific sustainment requirements or technologies.

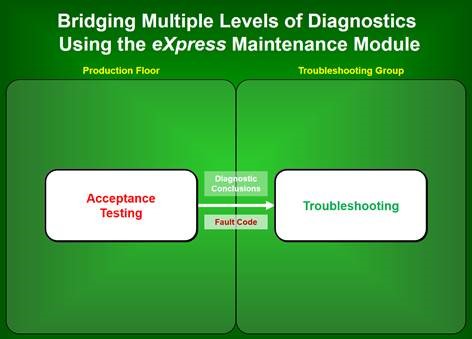

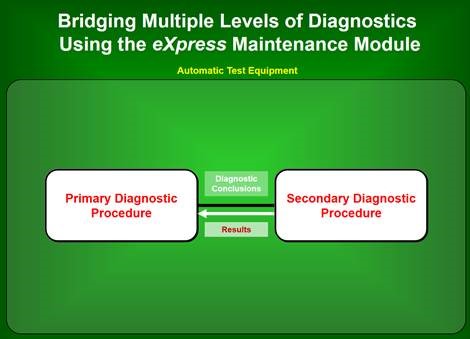

The series of images below describes this specific core capability of the eXpress Maintenance Module.

Transferal of Diagnostic or BIT Test Coverage Knowledge to the Operational Environment

Once we determine the immediate or ultimate long-term targeted objectives, we can rely on the eXpress Maintenance Module to write the script for the role of “diagnostic status messenger”, for coordinating any System Health Management, ATE or Guided Troubleshooting endeavors – and any mixtures requiring the coordinated diagnostic activities.

After determining the scope of the diagnostic objectives, we can examine the transferring, or “bridging” of the diagnostic “levels” as consistent with the sustainment objectives. The next four images depict a variety of typical applications where comprehensive diagnostic inferencing savvy will greatly benefit the success and accuracy of the “bridging” of multiple levels of diagnostics.

1) Integrating on-board IVHM to a Maintenance “Diagnostic Reasoner”;

2) Integrating Reported BIT status for continued use in Intermediate Maintenance Diagnostics;

3) Integrating BIT Coverage for continued use Guided Troubleshooting approaches;

4) Integrating Reported BIT status retrieved by ATE with conclusive Diagnostic Inferencing;

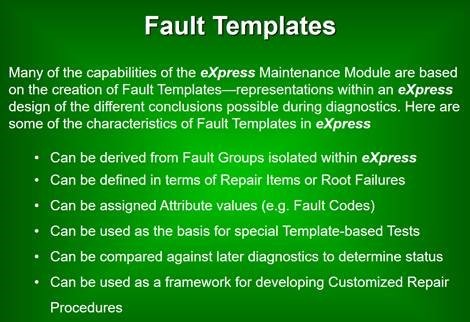

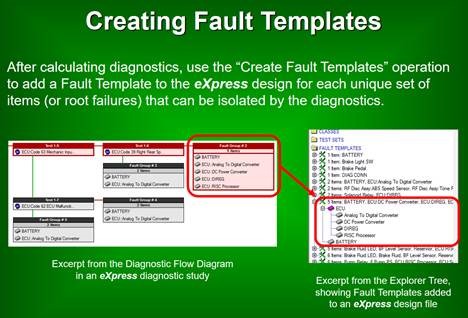

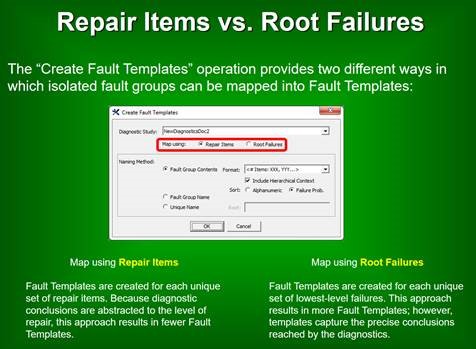

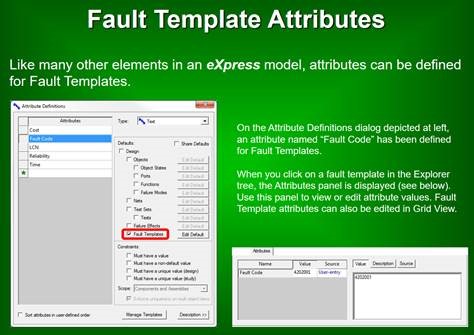

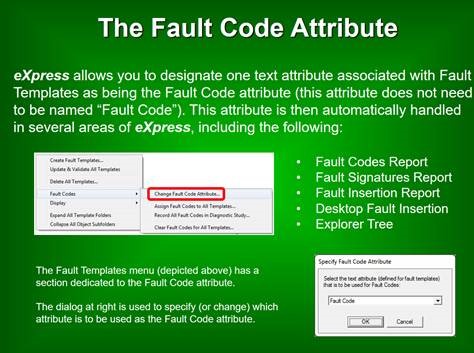

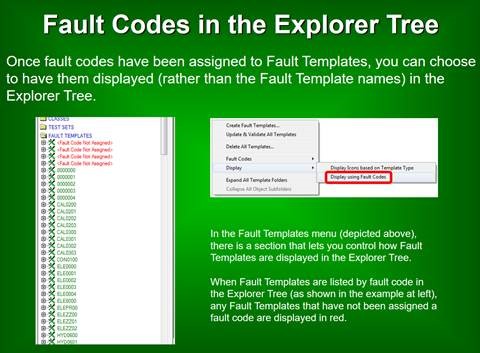

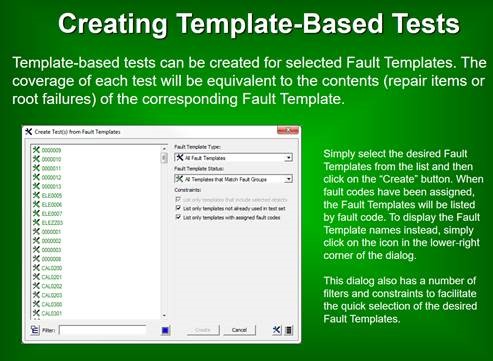

Creating Fault Templates

At this point, “Fault Templates” are able to be established that will facilitate the specific objectives of the maintenance criterion. The following five (5) images describe the purpose and procedure of the using of the Fault Templates:

The Fault Templates can be (re)used for multiple purposes during the Design Development Lifecycle. Because the ability to (re)generate and modify Fault Codes in the eXpress Maintenance Module is such a simple and quick endeavor, and because it is diagnostically savvy of the captured eXpress design, it can greatly circumvent difficult tasks such as the sequencing of test or repair procedures while conforming to accurate, effective or evolving diagnostic practices.

The Fault Templates provide an access corridor into the circumventing of the heavy “push-ups” involved in the interdisciplinary-dependent sustainment planning activities, such as in the developing of dynamic Technical Publications for Portable Maintenance Aids, IETMs, or a host of any other diagnostically-dependent efforts.

Since the Fault Templates seamlessly facilitate a myriad of customizable sustainment objectives, the design development and sustainment activities can realize more immediate ROI while fielding more effective, “Smart Lean” sustainment practices.

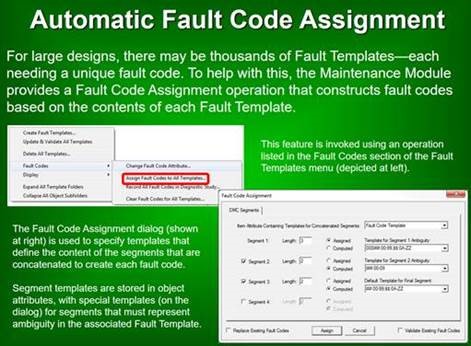

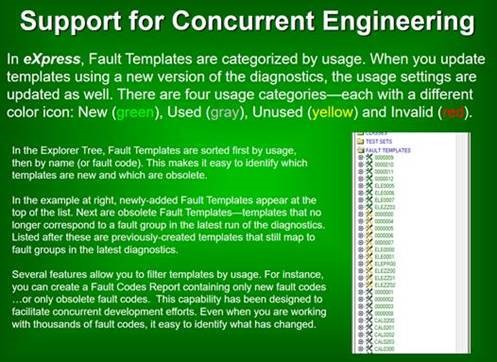

Automatic Fault Code Assignment

Once the BIT has been fully validated throughout the diagnostic design hierarchy, the Fault Codes can be “auto-assigned” to each Fault Group, or to whatever sustainment paradigm is deemed appropriate for the project. This is a core capability that can be exercised of any design captured in eXpress. Since the highly advanced eXpress diagnostics use both functions and failures wherever appropriate to best optimize detection or isolation, failures can be described at the component level as failure modes. An advanced feature in eXpress can be used to auto-generate failure effects from the failure modes, or often component failure effects are already available and then can be imported into any eXpress design(s).

Fault Codes can be represented as a Failure Effect or a combination of Failure Effects at the higher level of the design. When any specific group of failures can be determined to be a fault signature of a specific system failure, then Fault Codes (or, Error or Trouble Codes) are typically used to represent that combination of failure at highest level of the design – usually the Integrated Systems level.

The green charts below broadly describe the seamless process of establishing diagnostically-cognizant Fault Codes, that could be used for any embedded diagnostic capability, including IVHM, and then bringing that diagnostic savvy to any evolving sustainment paradigm:

Fault Codes can be assigned to fit any specific logistical requirement by using the highly customizable “Fault Template” mechanisms. In this regard, sustainment compatibility is fully synchronized with the design’s diagnostic integrity and the design’s maintenance procedures.

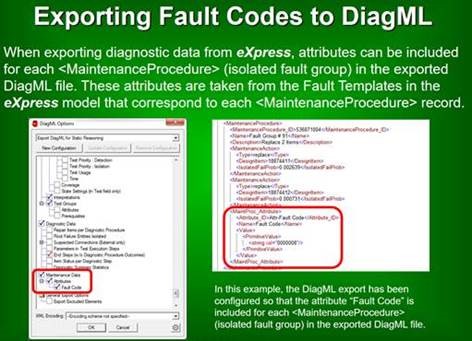

DiagML is a commonly used diagnostic data export facility that enables any design in eXpress to be (re)used in many other design simulation-based assessment analyses, and/or to target a myriad run-time diagnostic deployment methodologies, including ATE and IVHM.

Once any design changes or updates are (re)captured in eXpress, Fault Codes can be effectively and comprehensively updated and managed internally by eXpress in a manner of a few minutes, regardless of size or complexity of the design. Any changes in the Fault Codes will be identified and sorted for visual confirmation or (re)exported through DiagML for operational deployment.

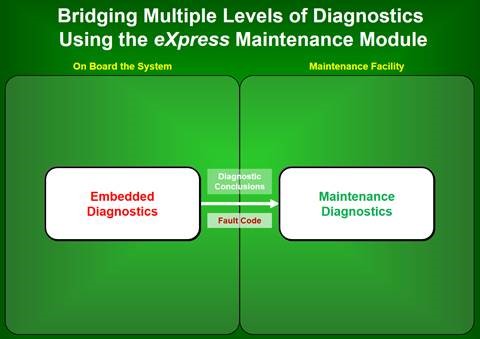

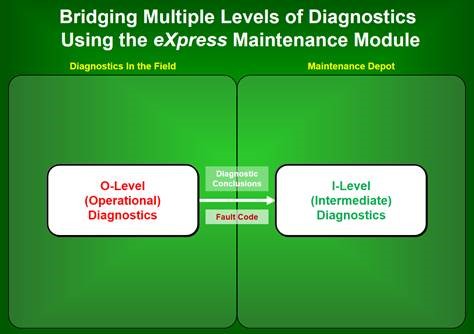

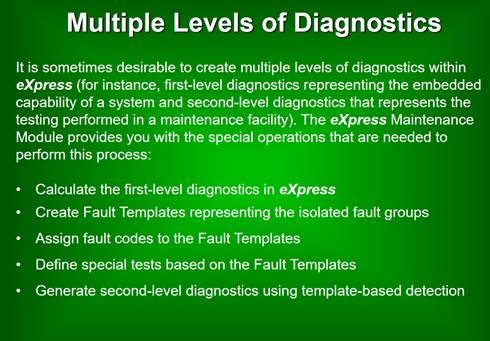

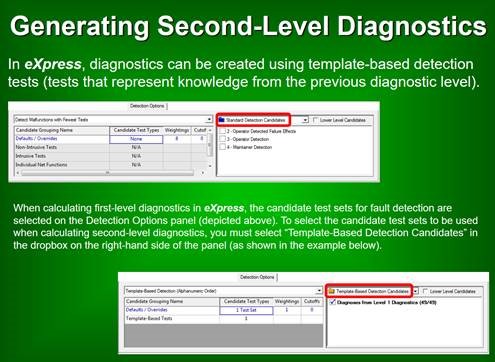

Multiple Levels of Diagnostics

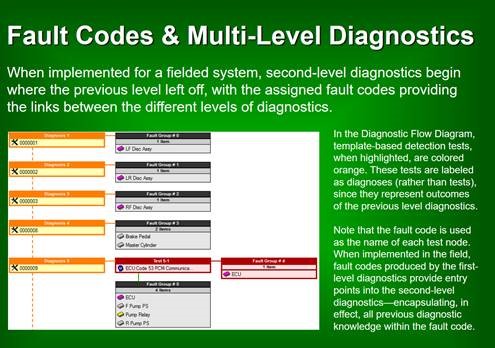

“Multiple Levels” of Diagnostics refers to eXpress’s unique advanced ability to seamlessly segment, retain and bridge, for example, the on-board IVHM, or any diagnostic capability to be fully resumed in an off-board, or second diagnostic level or methodology without discarding any diagnostic conclusions gained during the operational interrogation method(s).

The traditional method of “resuming” diagnostic levels (or “sessions”) from, for example, the “on-board” embedded BIT paradigm to the “off-board” next diagnostic level (or “session”) where on-board Fault Codes serve as diagnostic entry points without the ability to retain comprehensive Integrated Systems’ “diagnostic conclusions”, is one of the major causes of NFF’s, CND’s and RETOK’s.

The following six (6) images describe the general procedure for delivering all of the expert diagnostic acumen captured within the eXpress model and transferring it to the sustainment paradigm:

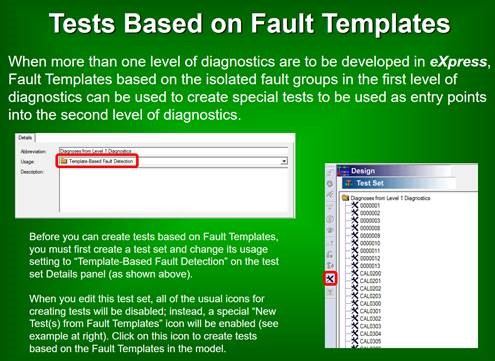

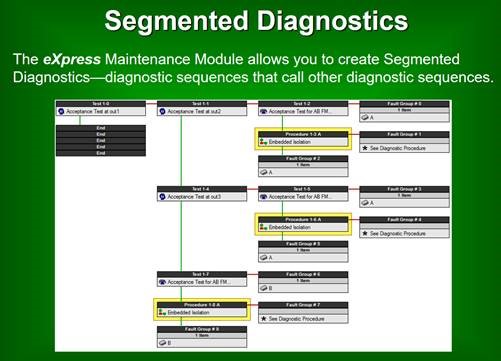

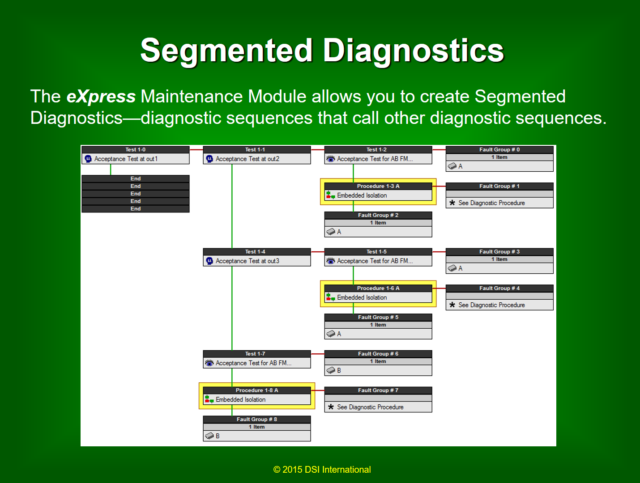

Segmented Diagnostics

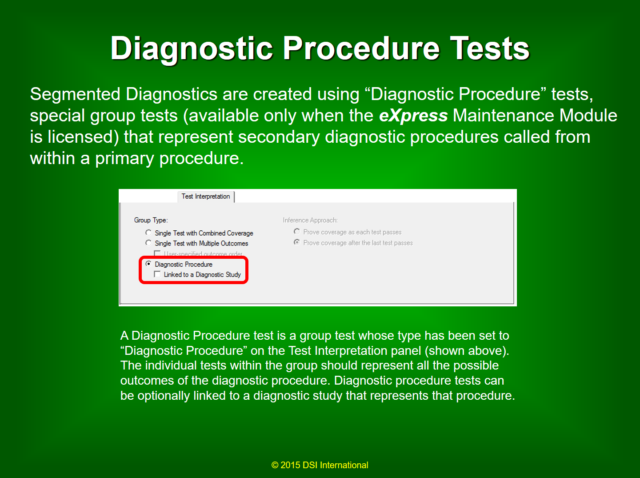

The ability to perform holistic and comprehensive diagnostics resides in the ability to retain the diagnostic conclusions gained from the First Level of the diagnostic interrogation – usually BIT and then bring that diagnostic knowledge to the next diagnostic level or session. This capability to break and reattach the diagnostics so seamlessly and comprehensively can be referred to as “Segmented Diagnostics”.

This is an inherent capability of the eXpress Diagnostics that enables comprehensive diagnostic design along with the first level diagnostic conclusions to be fully encapsulated and partitioned so that continued second level diagnostics simply calls a “Diagnostic Procedure” to resume without dropping any diagnostic inferences gained in the first diagnostic level. Refer to the following four (4) images below:

This is just a scratch on the surface of thie Assigning of Fault Codes capability featured by the eXpress Maintenance Module. DSI has greatly enriched this capability recently making it a sought-after, high-productivity tool within the ISDD Tool Suite.Please refer to the other highly advanced capabilities of the eXpress Maintenance Module that enable Maintenance Plans (repair or replace strategies) to be assessed, optimized and implemented.

Related Articles and Presentations:

Optimized Sensor Placement Strategies in eXpress to Reduce False Alarms

Boundary Scan in eXpress

The eXpress Maintenance Module

Test Types in eXpress

Related Videos:

BIT to Guided Troubleshooting

Diagnostic Validation Through Fault Insertion

COTS-Based Solution for Through-Life Support