Services

The diagnostic software module provides the industry’s most robust diagnostic and testability assessment tools. This diagnostic module provide those statistics normally described in MIL-STD 2165 as a baseline. It upholds the DSI legacy of bringing to industry a host of additions of value-added statistics and flexibility.

The eXpress Diagnostic Module now comes standard as an integrated module with the eXpress software package!

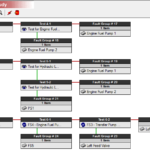

The diagnostic capabilities inherent to the eXpress Diagnostic Module meet or exceed the diagnostic design requirements for complex systems throughout industry and worldwide. The diagnostics in eXpress may be used to fully integrate all of your diagnostic information contained in other databases or spreadsheets into a single, scalable and immediately useful form. Suddenly, see the impact and utility that can be gained from leveraging this information by performing trade-off studies with eXpress using any of its more than 60 available diagnostic reports. Below are a few samples of these reports:

- Extensive Reporting

- MIL-STD 2165 Statistics

- Detection Coverage Reports

- Lambda-search Statistics

- Fault Group Statistics

- Function Probabilities

- Failure Mode Probabilities

- Flexible Hierarchical Expansion

- Controllable Test Candidacy

- Control over Modes of Operation

- Export to DiagML

Prognostics, PHM, IPHM, ISHM, IVHM, and any other Health Management System, ABSOLUTELY need to begin with the Diagnostics design! The only way to improve your ability to take advantage of some of these evolving new Prognostics and Health Management technologies is to prepare for their use by using eXpress’s Diagnostics prowess. The trade-off studies that can be performed iteratively and early, in the design phase using eXpress, will guide you towards optimal sensor placement and provide you with information to better make decisions involving system design alternatives, redundancies, reconfiguration, remediation, and maintenance strategies to best adapt to a changing environment. The diagnostic information contained within your eXpress model, can easily and instantly, be changed, modified, replaced, etc. to support new concepts, technologies and implementations, requirements, support activities, etc. at any point in the life of your system.

Using DIM for:

- Optimizing Test Strategies

- Development and Optimization of IVHM / ISHM

- Article: A Design Environment for Legacy Test Strategies

Optimizations with multiple goals can be at cross-purposes. For example, improving Availability may result in increased Life Cycle Cost. Finding solutions that satisfy multiple goals can be achieved incrementally by iteratively improving diagnostic capability. For each iteration, the most out-of-range goals are used to provide limits to drive new cases, thereby converging on a solution.

Meeting the Goals with Testability, Reliability and Maintainability Metrics

- Fault Detection / Fault Isolation Levels (FD/FI)

- System Mean Time Between Failures

- Mean Cost / Time to Repair

- Likelihood of Critical Events

- Inherent Availability

It’s important to recognize when changes to testing result in diminishing returns, an indication that design changes should be considered, or that the proposed changes to testing are ineffective. More sophisticated testing can involve greater development costs, often overriding any benefits which lead to its consideration. Similar changes made earlier in the design’s development, however, can achieve much of the same optimization at a greatly reduced cost. Optimization is about finding the balance between seemingly competing criteria.

A robust engineering environment, one that supports the complexities described here, requires a powerful diagnostics assessment and optimization tool. Properly considering the trade-offs between design changes and testing further requires a tool that incorporates systems engineering methodology. Finally, comprehensive reporting is a key capability in supporting required assessments.