Products

Diagnostic Design and Analysis

The diagnostic software module provides the industry’s most robust diagnostic design and analysis tools. eXpress diagnostics is capable of meeting the testability requirements of both the MIL-STD 2165 and IEEE-1522 and the needs of real-world troubleshooting diagnostics used in production, maintenance and health management systems.

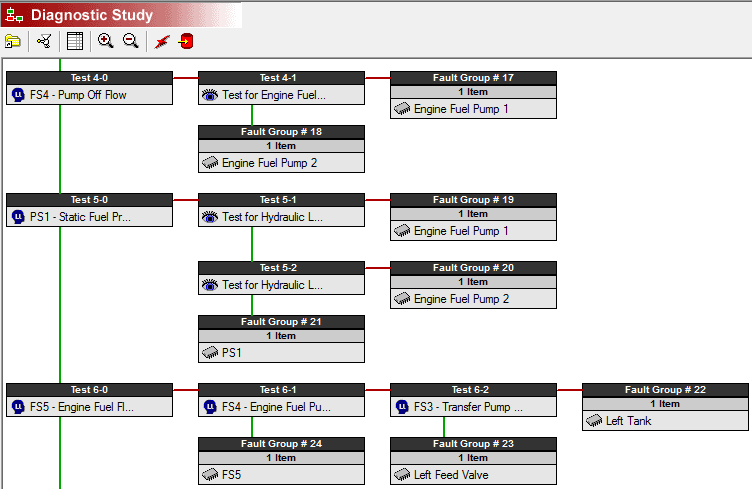

eXpress diagnostic works by using the tests and diagnostic relationships built in the eXpress model to calculate the best possible diagnostic troubleshooting flow which can be optimized for cost, time or criticality of failure. The diagnostics is fully scalable to small or large scale systems.

Prognostics when included with the diagnostic analysis may be used to provide details about the impact of the prognostics upon the diagnostics and critical safety events.

Diagnostic Analysis for Testability, Reliability, Maintainability and Critical Safety Analysis

The results of the diagnostic can be leveraged by performing trade-off studies with eXpress using any of its more than 60 available diagnostic reports. Failure mode and effect analysis (FMEA) can use the results of diagnostics to provide information about how the individual failure modes on the FMEA are detected, uniquely isolated, expected fault groups and fault signatures which is a list of all tests that would fail if the failure mode occurs. Fault Tree Analysis (FTA) can use the results of diagnostics to provide information about whether the critical failures and their associated causes are detectable and uniquely isolated. Prognostics when included with a diagnostic that is then attached to an FTA can be used to determine to what degree that the likelihood of critical failure is reduced by the prognostics.

eXpress Diagnostic Reports

eXpress provides many different reports to assist the design engineer to meet the needs of the primary goals of diagnostic engineering which including analyzing and improving system safety, maintainability, availability and cost-of-ownership. Many eXpress reports are designed to meet diagnostic engineering requirements for testability, reliability, maintainability and safety. Here are some of the more commonly used diagnostic reports:

Extending the Role of Product Lifecycle Management (PLM)

As designs are becoming more complex and as Systems Integrators are looking for non-intrusive methods to reduce development time while increasing collaboration and efficiency, eXpress’s Diagnostic Models (using “eXpressML“) can play an invaluable role in the integration of the design activities within the PLM environment. As each organization typically has its own preferred methods to work to Model-Based Systems Engineering (MBSE) paradigm, eXpress provides a robust canvas to enable the integration of the diagnostics throughout design development to cross-validate iterative real-time inputs from interdisciplinary design activities.

Diagnostics Design for Production and Health Management Systems

Troubleshooting, maintenance and health management systems such as PHM, IPHM, ISHM, IVHM can take advantage of an unmatched feature set within eXpress to: Evaluate the testability of a system, perform trade studies to reduce cost of ownership and increase system availability, assess the impact of prognostics and diagnostics upon critical safety events, and manage repair and maintenance tasks such as assigning fault codes and setting up complex replacement metrics.

Using eXpress Diagnostic in Run-Time Environments

eXpress diagnostic can be easily exported from eXpress using the DiagML (Link to Support “4-1-1 DiagML”) export which is an Xml format developed for diagnostic designs. The DiagML design can then be imported into a variety of tools include: the Run-Time Authoring Tool, STAGE, and 3rd party diagnostic tools.

Compatible with the “Automatic Test Solution”, or ATS

eXpress Diagnostics can provide the diagnostic reasoning or test logic for any capable Automatic Test Equipment (ATE). Additionally, the seamless integration of the diagnostic sequencing can be exported directly into the Test Requirements Document (TRD) with DSI’s TRD Module for RTAT (see below) or as interoperable with any capable third-party TRD tool or internal processes. The highly-validated eXpress diagnostics can then be used to drive the diagnostic strategies in the companion Test Program Sets (TPS) that of the capable Automatic Test Systems in the United States, including:

NGATS – Next Generation Automatic Test System – US Army

VDATS – Versatile Depot Automatic Test System – USAF

eCASS – electronic Consolidated Automated Support System – US Navy

Publishing with the Run-Time Authoring Tool (RTAT)

When the exported DiagML is imported into the Run-Time Authoring Tool the design can then be publish to:

- The eXpress Design Viewer for technical review.

- DSI Workbench to be used in the troubleshooting environment.

- Marvin Test Systems ATEasy Diagnostics.

- Test Requirement Documents (TRD) directly (via TRD Module) or indirectly to support Mil-Std. 1519.

- S1000D Xml format used in a variety of 3rd party tools.

The Run-Time Authoring Tool is used to prepare the diagnostic design for use in a troubleshooting environment. This includes:

- Adding design images which can be customized to respond to the diagnostic highlighting suspects and popping up messages to focus the technician to important details

- Adding reference documents tests and objects in the design

- Adding test procedures and repair procedures

- Configuring the design to import test results from automated test equipment and built in tests and report configurations.

- Configuring custom design panels to display specific required information to the technician

- Configuring custom reports for use by the technician

Publishing to ATML format with ATML Pad

Test and diagnostic tools which use the automatic test and mark-up language or ATML are support using ATML Pad converts the diagnostic design from the eXpress DiagML format to the ATML.

Using ATML Pad tools such as National Instrument’s TestStand have a direct path between the diagnostic design developed in eXpress and the test environment in National TestStand and other related tools.