Solutions

Designing for IVHM or on-board Health Management

The Value of “FUI” Inherent to eXpress

The eXpress diagnostic modeling environment is essential for determining the diagnostic designs’ ability to “Uniquely Isolate” any failures (or loss of function). This capability, designated as “FUI” in eXpress, enables the assessment to determine if the design is able to isolate between the sensor and any of the functions contained on the object that is being sensed.

More specifically, the ability to identify where the design is unable to discern between functional failures due to the inherent diagnostic constraints of the design, can invaluable information during design development to enable proactive opportunities to perform immediate low-cost design changes. For any BIT reporting a failure during an operation, this advanced FUI assessment capability is a core capability within eXpress when utilizing the eXpress FMECA Plus or eXpress FTA Module. As an integral activity during design development assessment, this capability identifies where any of these, otherwise unknown design weaknesses, are occurring typically within any design, or as a result of integrating other designs into any higher level design.

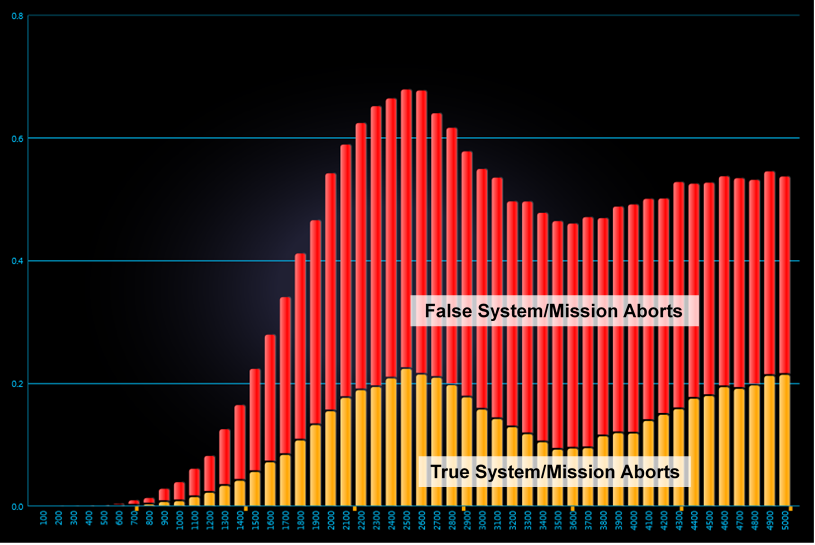

When functional failures are not able to be uniquely isolated in an on-board Health Management system, for example, the instantaneous corrective action to mitigate the assumed loss of a more severe functional failure, may be to abort a mission. Such a corrective action would be warranted if that functional failure actually existed. But instead, if a benign functional failure occurred but unable to be diagnostically separated from any the loss of a more severe failure, then the most drastic corrective action for any of the possible failures will be executed. This is just one typical example of how unknowingly weak diagnostic design can absolutely lead to many False indications of failure such as False Alarms (FA) and in response, lead to the initiation of many repeated incorrect corrective actions such as False Mission Aborts (FSA).

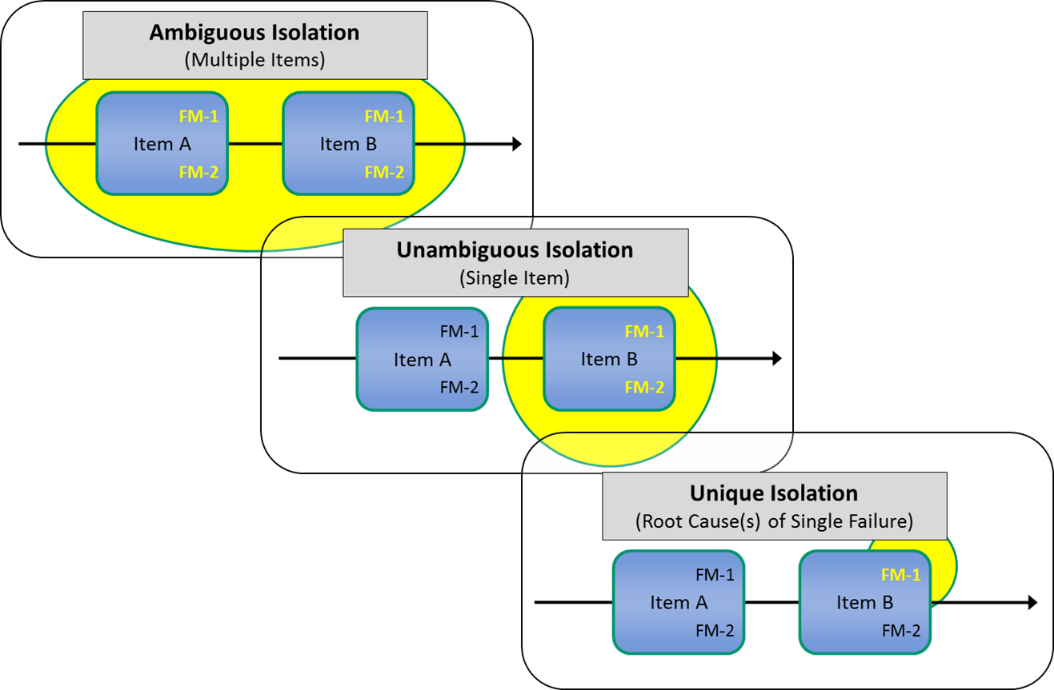

The depiction above, describes the difference between being able to isolate failures in terms of:

- The Fault Group – Where further isolation is not able to be performed beyond or between two or more replaceable components (Ambiguous Isolation)

- Any Single Component – Where isolation between any other components in a fault group is able to performed, yet further isolation between all failure modes on that component is not able to be performed (Unambiguous Isolation).

- Any Failure Mode – Where isolation between any other failure modes on a single component is able to be performed (Failures Uniquely Isolated, or, “FUI”)

Systems’ Integrators have the option to leverage the captured eXpress diagnostic design models in the generation of “eXpress output FMECAs”, capable of cross-validating the data contained therein with the designs’ Fault Tree Analysis (“FTA”), and visa-versa. This ability to “toggle” from, or back to, the eXpress FMECA and the eXpress FTA, which is essentially, the diagnostic designs’ “turn-key” automated, “top-down” view of the FMECA.

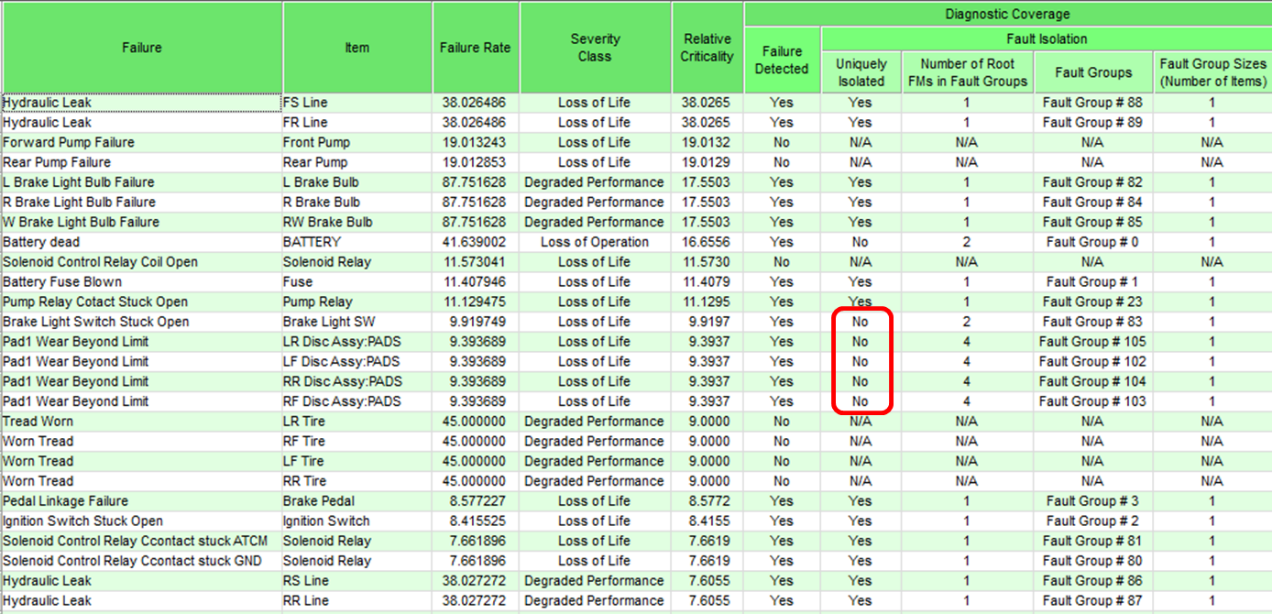

The eXpress FMECA is totally customizable that can present the data in any form from the “standard” MIL-STD 1629A to take on any form only limited by the data captured from Reliability, Maintenance and Diagnostics Engineering. This enables the producing of any common standard reliability assessment as well as substantially more enriched design assessment products that also considers the capabilities of the fielded asset in turnkey integrated design assessments. Below is a closer look at a turnkey chart produced from the eXpress FMECA Plus.

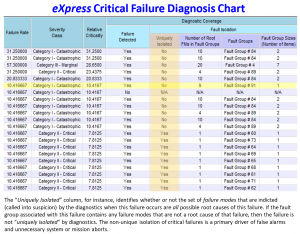

One of the turnkey eXpress FMECA Plus configurations is the “eXpress Critical Diagnosis Chart,” is shown above. It allows the viewer to examine a “Uniquely Isolated” column indicating whether the fault group that is isolated for this failure contains only root causes of the given failure. If the fault group contains any failure modes that are not a root cause of that failure, then the failure has not been uniquely isolated by the diagnostics. The non-unique isolation of critical failures is a primary driver of false alarms and unnecessary system or mission aborts.

When sufficient design data is captured to fully support the “toggling” from the integrated systems FMECA and the Fault Tree Analysis, the eXpress FTA will also carry the knowledge of FUI into every cut set branch of this System Safety Assessment as described in the section below entitled, “Reuse: Safety Analysis and Risk Mitigation”.

This is a diagnostic-informed Safety Assessment product is a unique capability from the eXpress model that boldly informs the customer of how likely the fielded asset is able to detect and uniquely isolate any specified critical failure in that branch of the Safety Assessment as identified in the eXpress FTA. This will better ensure that the most effective corrective action or mitigation is able to be performed.

Reusing eXpress Models: Operational Support Simulation

The ISDD process, through the eXpress diagnostic modeling environment, is able to output an eXpress diagnostic design data file that is directly importable to a fully integrated sustainment simulation companion tool, or “STAGE”.

The captured diagnostic design data used to produce assessments (FD/FI, FMECA’s and many other required assessment products) is used directly in STAGE to seed time-based sustainment metrics. From the STAGE simulation, such stochastic values as calculated for FA, FSA, MTBCF, MTBSA, MTBUM, RUL and well over 200 additional (and ground-breaking) sustainment-related graphs are produced. “STAGE” provides a pallet for the assessing of virtually an unlimited assortment of operational support and Health Management simulation calculations. With respect to the IVHM or any design, the STAGE simulation is able to simulate the occurrence of failures of components (and based upon their respective diagnostic design impact) in accordance with their assigned failure rates over a selected sustainment horizon (“lifetime”). In this manner, the designs’ inherent diagnostic architecture becomes exposed.

Below is an example of the impact of FUI in a graph showing the System or Mission Aborts in STAGE:

An additional capability of the STAGE operational support simulation is that the calculations consider the impact of maintenance activities. In this manner, the results computed by STAGE reflect the value or costs associated with any proposed sustainment philosophy. When the diagnostic design is augmented with any selection of sustainment “mixtures” of predictive (PdM & CMB), preventative (RCM) and corrective maintenance, STAGE will consider these parameters when producing the selected simulation graphs.

The graph(s) produced from the STAGE simulation show the strengths and weaknesses of the integrated systems’ diagnostic design in a broad range of critical assessment graphs along with any selected interrelated costing or performance-related graphs. All of the STAGE graphs can be immediately exported to MS PowerPoint while the data contained in the graphs can be, likewise exported to MS Excel, which facilitates ease of data sharing. This is just another immediately available design & support assessment collaboration option requiring no additional data input.

While forcing continued traceability to the diagnostic designs’ maturation in both the development and the sustainment life-cycles, eXpress models may be initiated during any phase of the design development process, but offers increased value and opportunity when instituted as early as possible in the design development life-cycle. Accordingly, the eXpress models can be used or modified as needed, to perform iterative and “current” assessments of the diagnostic capability of the Integrated Systems’ diagnostics design. When used early in the design development phase, this sharing and leveraging of interdisciplinary data and assessment product artifacts provides unique and timely feedback to Reliability and Maintainability Engineering.

Combining Talent: eXpress and IVHM Design

In conjunction with the advanced eXpress Diagnostic Modeling capability, the host embedded on-board IVHM application is able to provide an efficient framework for organizing salient knowledge acquired from the subsystem or selected system(s) under analysis. The diagnostic reasoning activities are ultimately capable of achieving consistency with the diagnostically-optimized IVHM capability from the process of being vetted in the eXpress diagnostic modeling paradigm. In this manner, any BIT failures (and “Diagnostic Conclusions based thereon) retrieved by the on-board IVHM application are able to be “bridged” to the off-board sustainment paradigm.

Contemporaneously, and while the IVHM performs its function on-board the vehicle, any BIT data retrieved in the off-board sustainment environment can be diagnostically interpreted in a more comprehensive and diagnostically-conclusive manner. This is the result of influencing the diagnostic designing of the on-board IVHM to, and, for the “bridging” of the diagnostic designs’ BIT data to more effectively commence the off-board second level sustainment activities.

The difficulty in creating an IVHM diagnostic system lies in designing of a diagnostically-savvy knowledgebase for the physical system because of inevitable tradeoffs between complexity and completeness. Of course, this must begin by first establishing of the “diagnostic integrity baseline” of the “Health Management Reasoning” and its role as an integral component of the broader, more inclusive, on-board IVHM architecture. “Cost-benefit” tradeoffs are effectively attained within the eXpress modeling paradigm, given a collaborative and cooperative working environment with equally shared vision and objectives.

Reuse: eXpress Embedded Reasoner maximizes On-Board Health Management

Once the design of the On-Board Health Management (OBHM, ISHM, IVHM, etc.) has been either influenced for the reusability of the diagnostic status data collected (as is a typical benefit when captured in eXpress), then it can be leveraged in a myriad of advanced diagnostically-enriched sustainment activities. Beginning with a diagnostically savvy On-Board capability, the eXpress Embedded Reasoner operates with the On-Board Health Management System to perform the non-safety critical diagnostic reasoning objectives in a fraction of a second. It is able to perform diagnostic sequencing based upon retrieved BIT status data since the eXpress Embedded Reasoner computes the exact diagnostic inferences from this data.

When any advanced on-board Reasoner or the eXpress Diagnostic Reasoner is used, comprehensive diagnostic inference data is “bridged” to the off-board, second maintenance level diagnostic paradigm. The major discriminator is that the eXpress Embedded Reasoner enables the off-board diagnostic session to begin with concise diagnostic conclusions gained from its tight integration with the On-Board Health Management System. Later, when the next diagnostic or maintenance session begins in the field, depot or laboratory, all of the diagnostic conclusions gained in the eXpress Embedded Reasoner provide for much more diagnostically accurate sustainment environment.

Reusing: Safety Analysis and Risk Mitigation

The eXpress FTA is another assessment product output of the eXpress modeling paradigm, which is traceable to the diagnostics design of the (evolving) integrated system. The eXpress modeling paradigm is able to (re)use existing data or mimic earlier created FTA output representations from FTA’s created in a separate tool, method, or by a third party supplier, which are traditionally created in a manner that is separate and adjunct to the designs’ diagnostic designs’ architecture. Traditionally, FTAs have not been concerned with the integrated systems diagnostics design architecture, which is an ongoing costly weakness of that traditional approach. Some of the costs will be expressed and/or implied within this paper and some of those ongoing costs become more painfully apparent when the burden is shouldered by those without “a dog in the fight”.

The natural path forward is for the Systems’ Integrator is to produce the FTAs for or within their company-required tools or methods. But since the Systems’ Integrator is a “systems integrator”, it will be also need to remain open to receiving FTAs produced by other suppliers in other methods and tools – and there’s a likelihood that some those major subsystem suppliers may have produced, or intend to produce eXpress models. In this regard, the eXpress modeling environment allows for Systems’ Integrators to have it both ways.

Regardless if the traditionally produced FTAs were generated internally by the Systems’ Integrator, by any external third party, or may otherwise exclude costly design updates into existing FTAs, the establishing of the eXpress FTA provides an innovative alternative to such traditionally-rigid FTAs. The eXpress FTA gracefully extends the utility and ease of (re)producing and maintaining an evolving, uniform “integrated systems” eXpress FTA. This enables the eXpress FTA to seamlessly and continuously reflect design updates or the occurrences of maintenance activities throughout the sustainment life-cycle.

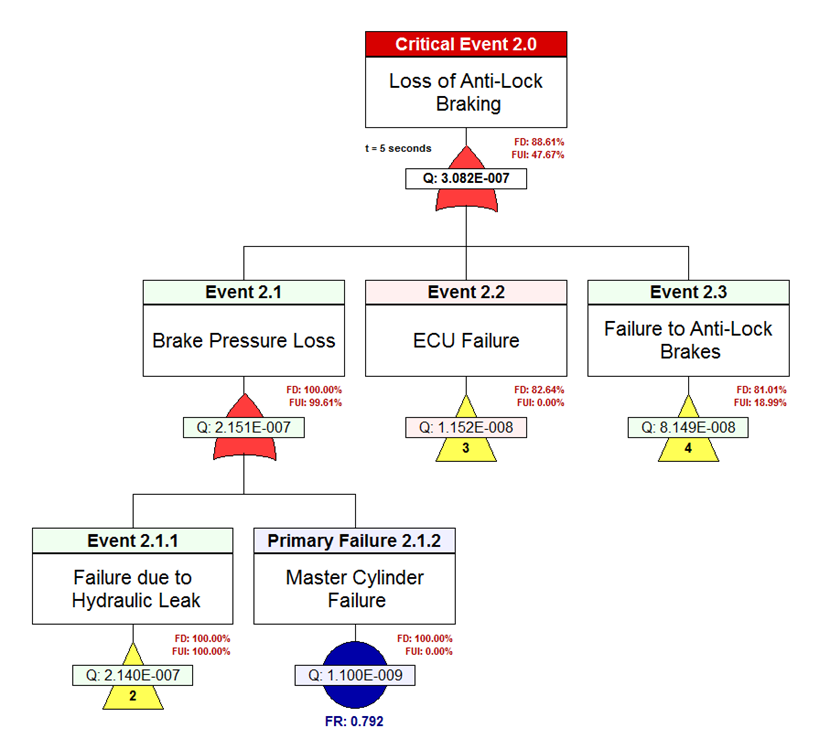

Below is an example of the impact of FUI in a turnkey FTA output from eXpress:

The eXpress FTA is a diagnostic-informed Safety Assessment product that is a unique capability from the eXpress model. As such, it boldly informs the designer/owner/operator of how likely the fielded asset is able to detect and uniquely isolate any specified critical failure in that branch of the Safety Assessment as identified in the eXpress FTA. This will better ensure that the most effective corrective action or mitigation is able to be initiated rather than the most aggressive corrective action as is the case with traditional implementations that dismiss the need for superior diagnostics design.

The eXpress FTA is a diagnostic-informed Safety Assessment product that is a unique capability from the eXpress model. As such, it boldly informs the designer/owner/operator of how likely the fielded asset is able to detect and uniquely isolate any specified critical failure in that branch of the Safety Assessment as identified in the eXpress FTA. This will better ensure that the most effective corrective action or mitigation is able to be initiated rather than the most aggressive corrective action as is the case with traditional implementations that dismiss the need for superior diagnostics design.

Reuse: Reducing FTA Efforts by 50-80%

This eXpress FTA allows for the immediate top-down visualization of the design level effects of the primary failures contained in the selected level of analysis as identified in the companion FMECA design(s). Meaning, if the FMECA is targeting the FTA to include the component or box level failures as primary failures, then the level of the FTA analysis can support either alternative, or as limited by the level of FMECA data available.

The eXpress FTA is sufficiently rich to enable the interactive inclusion of “and” gates and polling “or” (“K of N”) gates, external events and a host of other symbols typically used to represent more complex interdependent failure events. A host of other fundamental capabilities are also characterized within the eXpress FTA to maintain a sense of familiarity with more experienced folks delving in this aspect of the Reliability Engineering discipline. Some of those typical visual hallmarks include the “probability of occurrence” or “Q” calculation for any “cut set” contained within the eXpress FMECA, and thereby inference, the integrated eXpress FTA.

Where the separations begin to occur when describing the diagnostically-influenced FTA from the adjunct traditional FTAs, is that the eXpress FTA is cross-validated with the FMECA and the diagnostic capability of the design interrelated therewith, which opens the headroom for enriched “diagnostically-savvy” FMECAs and FTAs. This is a discriminating capability because, not only are all of these assessment products capable of being updated instantly, consistently and comprehensively, but so is typically experienced with its companion (evolving) diagnostic paradigm.

Remember – Maintenance activities forever change the failure characteristics of the fielded system(s).

Reuse: Enriching the FTA Assessment to Include Diagnostics and Prognostics

In briefly highlighting an advanced capability that becomes part and parcel within the eXpress FTA assessment product, is the ability to discern which percentages of the condition (calculation) leading to the undesirable event are able to be “uniquely isolated” in that specific “branch” or “cut set” representing the occurrence of that undesired event. This enables uniquely valuable “inside” information that, from an integrated systems design development or sustainment perspective, is able to determine the portion, if any, of the undesired event is able to be detected or isolated as determined within the constraints of the test coverage of the BIT for and by, any particular operational state, for example. The eXpress FTA also enables the inclusion of “Prognostic Events” to be fully integrated and considered in the calculation of the probability of occurrence of undesired events, given that prognostics or “Predictive Maintenance” actions will be an integral piece of the maintenance philosophy.

As a result, the companion eXpress FTA baseline architecture is automatically generated once the integrated systems and the FMECAs are fully captured in the eXpress models. This is performed early in the design development life-cycle, which will greatly enrich and support the IVHM design development paradigm. By capturing all interrelationships and interdependencies subsystems’ functional and failure effect propagation, eXpress (and its companion ISDD tool suite) influence the IVHM design the opportunity to take advantage of robust and agile diagnostic alternatives that are not technologically or cost-effectively possible for traditional IVHM designs.

Reuse: Enhanced Off-Board Guided Troubleshooting

The most obvious sustainment value begins with the eXpress Diagnostic Models as they are also (re)used to support the production or maintenance environment(s). In this implementation, the captured diagnostic design will instantly improve the accuracy and effectiveness of maintenance tasks via any compatible technology or Portable Maintenance Device (PMD), Portable Maintenance Aid (PMA), Integrated Electronic Technical Manual (IETM), etc.

This Guided Troubleshooting Application can be hosted or accessed:

- Via an API to be hosted as either a fully-featured or back-ground Reasoner in supporting any native GUI for either MS Windows or VxWorks Operating Systems

- Via DSI Workbench that can be used on a portable laptop or workstation in the field or laboratory environments.

This interoperable architecture provides the technician or maintainer with the ease of access to any preferred GUI without losing the benefit of the eXpress diagnostic design knowledgebase. This flexibility is not only greatly enhanced, but the guided troubleshooting performance is equally accurate, consistent and decisive for various skill levels.

Since traditional embedded Health Management designs dismiss the need or ability to determine any knowledge of “fault isolation groups” from the retrieval of triggered on-board BIT failure codes, the “bridging” of the diagnostic conclusions able to be gained from the on-board assessment(s) are essentially not existent. Again, this is a typical (costly) shortcoming of traditional on-board to off-board sustainment approaches, which ultimately surface in the sustainment lifecycle as NFF, CND and False Removal cost drivers.

That said however, and when the off-board diagnostic sustainment paradigm is able to derive diagnostic conclusions, due to its inclusion in the design development of the IVHM and any related BIT codes, it will enable the off-board diagnostic solution to “bridge” the sustainment implementation(s). This integrated and “bridged” sustainment approach will allow for more intelligent back-end diagnostic data exchange schemas, tools or technologies (ATML, S1000-D, etc.) to be inclusive and instantly enriched. Going forward, it’s easily adaptable to technology evolution. This evades the inevitability of on-board IVHM from being a mostly rigid and costly implementation to update for bridging to off-board diagnostic paradigms in the future. Going further and as failure resolution is gained from the off-board guided troubleshooting paradigm, the history of these resolutions is captured in any robust or commercially available database tool structure.

As the maintainer steps through the off-board guided troubleshooting experience in this BIT to Guided Troubleshooting demonstration video, any prior failure resolutions are able to be accessed contemporaneously with the UUT design knowledge. This is another unique quality that allows the maintainer to be guided by empirical knowledge (past diagnostic resolution given current diagnostic status), but also provides the design knowledge to the maintainer. In this regard, the maintainer isn’t going to be surprised by First Failures (cons of case-based reasoning) and the maintainer can leverage past experience (pro of case-based reasoning). But going forward, this new off-board paradigm will also enable the inclusion of prior or existing fault resolution data from legacy systems. This enables its use to benefit from being included early in deciding sustainment alternatives and also facilitates a gateway to add new value to existing legacy paradigms where sustainment costs have already exceeded their welcome.

With ISDD, Program Managers and System Integrators have the opportunity to greatly enrich and more clearly define the sustainment capability and its expected value throughout the sustainment lifecycle. An environment that fosters and prioritizes effective “Design for Sustainment” savvy during the “Design Development” lifecycle not only ensures immediate value from reducing repeated parallel and inconsistencies inherent to independent design efforts, but then leverages this truly integrated interdisciplinary approach by injecting “diagnostic intelligence” in all of the ensuing supporting capabilities.