Solutions

Incorporate Multiple Technologies into a Single System Assessment

Introducing “ISDD” to the Systems’ Integrator

Many of the ideas and concepts regarding the targeting of an “agile” maintenance strategy for System or the System of Systems (SoS) begin with the formalizing of a unified approach to collectively capture the functionality of the participating designs into a robust integrated systems’ design development and process. But this design development process must be able to fully assess not solely the top-down functional allocation Systems’ Design and Sustainment Requirements (Operational Availability, etc.) but also be fully positioned to assess and validate the functional and failure cause (root cause) propagation from the bottom-up.

Integrate Lower-Level Subsystem Designs

Designing for the System or Vehicle sustainment lifecycle must consider the adopting of a well-planned diagnostics engineering process using that facilitates a multi-organizational approach to advanced and robust tools that do far more than simply “share data”. However, initially, the sharing of diagnostically-relevant design data should be sufficiently robust to be performed between design disciplines (e.g. Reliability, Maintenance or Diagnostics Engineering) and partnering companies and while seamlessly crossing design domains – effectively and comprehensively. This “shared” data will be restructured in a collaborate environment and then fully integrated by Systems Integrator.

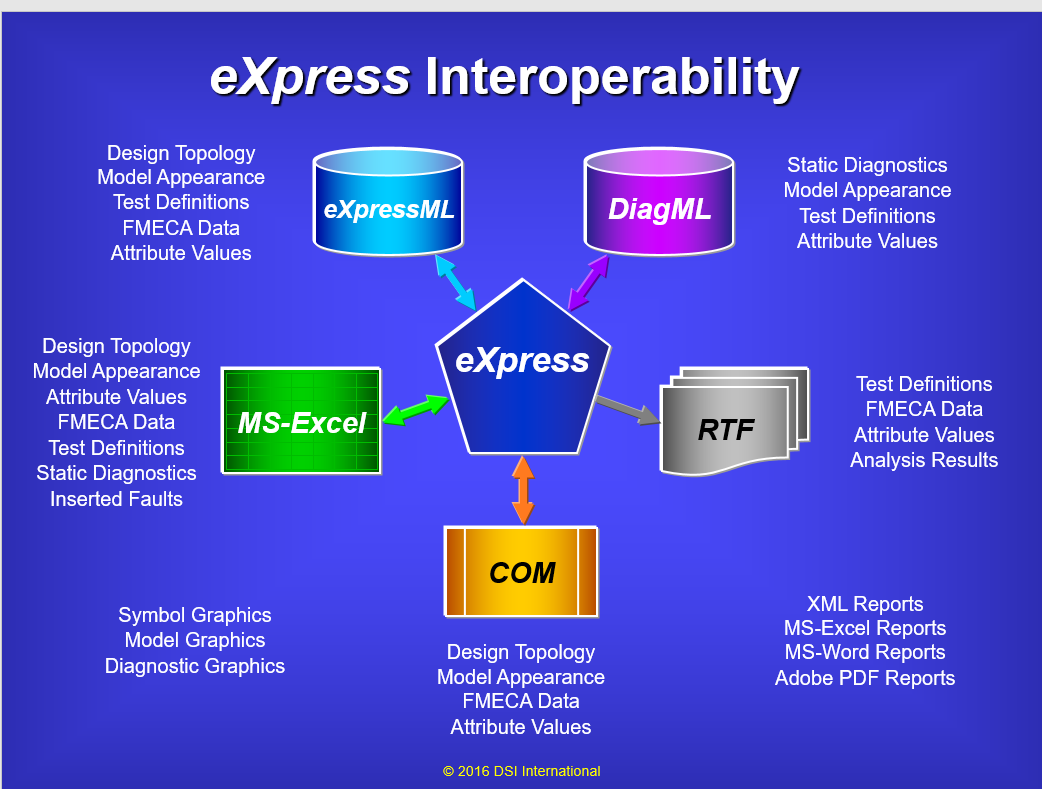

The diagram above depicts the various forms of data that can be imported or exported from eXpress

Importing Data from Spreadsheets

There are different ways that data can be imported into eXpress from Microsoft Excel spreadsheets. Of all the different methods of automatically bringing external data into an eXpress model, the most frequently used are the various Microsoft Excel spreadsheet imports. This is due primarily to the widespread practice of using Excel worksheets as either repositories of project data, or as a preferred format for representing information that is able to be shared by similar or complimentary engineering efforts.

eXpress allows a wide variety of data to be imported from spreadsheets:

- Import the topology of the design – Depending upon what data you have available, this can range from simple connectivity to detailed functional definitions.

- Import the placement and appearance – Any relative sizes of objects can be similarly represented to aide the communication with the eXpress model .

- Imported attribute values – Attributes may be project-specific values or text that can be associated with any of the basic elements in a model. Commonly imported attributes include item failure rates, part numbers, circuit IDs and Logistics Control Numbers.

- Import Reliability data – Imports of such data typically includes failure rates, failure modes, failure effects and severities.

- Import more detailed data – Project spreadsheets sometimes contain information that can help automate the test definition process. If, for instance, a Reliability spreadsheet includes a column listing the BIT associated with each failure, you can import these BIT definitions into eXpress.

- A variety of other data can also be imported from spreadsheets, including static test sequences, user-defined inferences to be applied during diagnostics, lists of faults for the Desktop Fault Insertion (DFI) capability, and events used by the Fault Tree Analysis (FTA) module.

Many of these different import capabilities are demonstrated in videos in the “Importing Data from Spreadsheets” series. This series of videos begins with an initial demonstration of the design Topology Import. The use of this import enables the rapid construction of a basic model from elements in an Excel spreadsheet.

User-Defined Inferences and Seeding Diagnostic Deployment

User-Defined (diagnostic) Inferences can also be deployed when diagnostics must follow test sequencing based upon pre-determined diagnostic conclusions associated with any individual or set of pass or failed test results. Such User-Defined Inference is typically applied in lesser-sophisticated military applications or more commonplace in an assortment of industrial or commercial applications where diagnostic design was not intended or funded to be effective or optimized. Such User-Defined (diagnostic) Inferences can be replicated and included, in whole or in part, within any eXpress model, but at the risk of the initially-deployed diagnostics being substantially below the minimum standards of DSI’s customary eXpress-derived diagnostic capability.

For more advanced or custom uses of the eXpress UDI Module, where the knowledge of the design is captured within the eXpress model, the UDI capability can be used to effectively augment known diagnostic inadequacies or be used to consistently facilitate maintenance requirements or specific programmatic procedural actions.

Combining Multiple Technologies and Design Domains

Once the diagnostic data sharing paradigm has been instituted, ISDD establishes an enriched integrated diagnostic design development environment that, while protecting the sensitivity and proprieties of any externally-supplied design data, enables a comprehensive and agile data integration mechanism for the System Integrator to “integrate” and “repurpose” the shared data into the System, regardless of design size, complexity or mixture of Design Domains:

- Digital/Electronic Components (Circuit Boards, etc.)

- Mechanical/Electrical Systems

- Hydraulic/Pneumatic Systems

- Software Inputs to Designs

Concurrent Engineering or “Scalable” Design Development

The ISDD design development process fosters the diagnostic integration of both interim and final development deliveries of the design’s related diagnostic engineering data. The diagnostic engineering data will minimally include the determining of the most optimum test placement of sensors, BIT or test observability, if any, by the describing of the test coverage per each test per any operational mode or condition of the design as a function of the operational System.

The comprehensiveness of the diagnostic data results from the implementation of the ISDD process, which permeates through traditional design discipline boundaries. As the diagnostic design data is provided by any companion design discipline or external team partner, ISDD establishes a structure that produces an evolving and “living” diagnostic model as it integrates each design piece throughout the design development lifecycle.

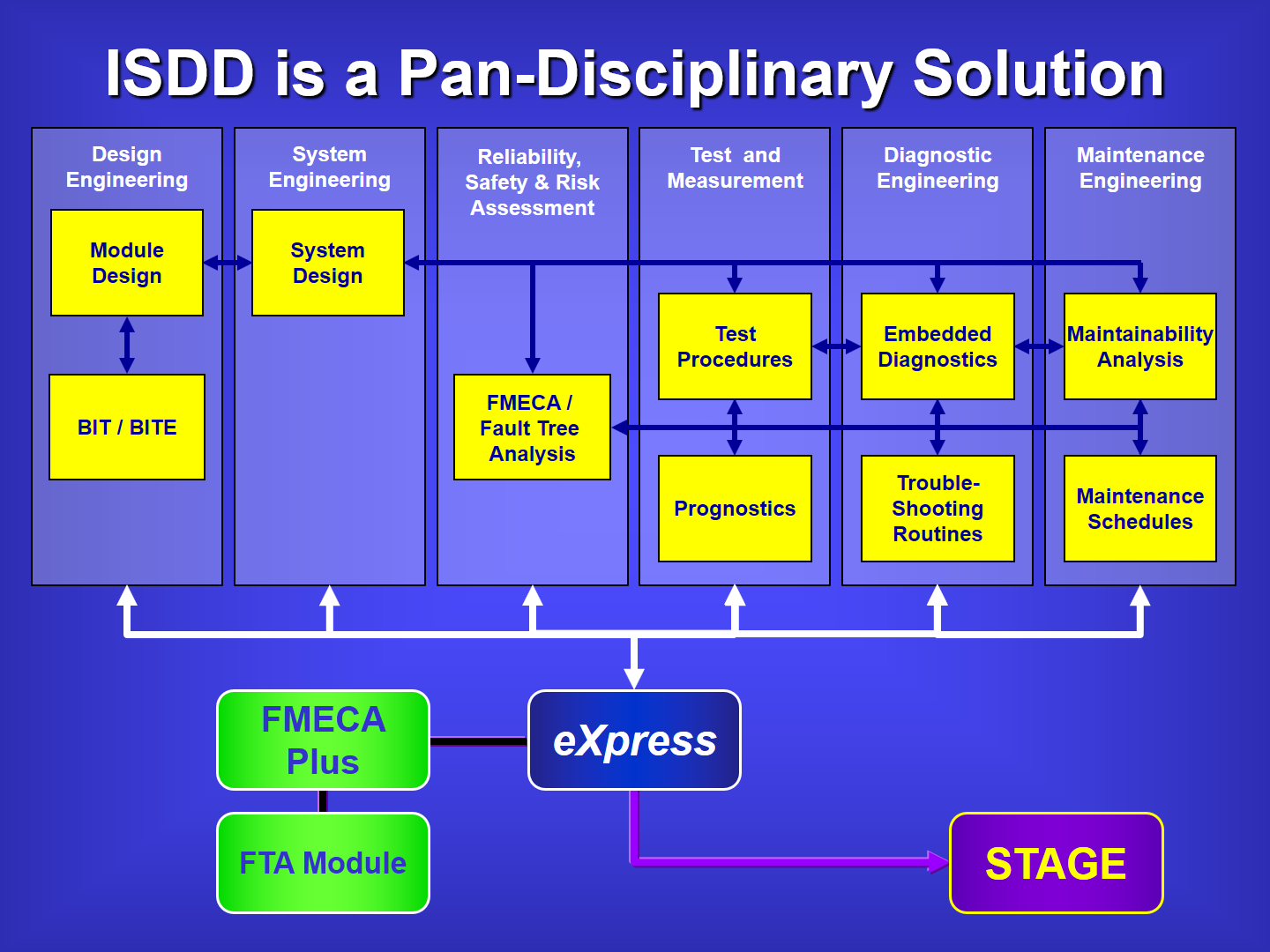

The chart above depicts the general responsibilities of each design discipline during the Design Development Lifecycle

Assessing the progress of the diagnostic capability of any developing piece or combination pieces of the design can be assessed at any time throughout the diagnostic development process. Therefore, at any point during development any progress towards the diagnostic requirements can be tracked, modified or enhanced as the design progresses. Design decisions (parts selection process, test point selection, maintenance philosophy, diagnostic reasoning technologies, etc.) can also be evaluated against the System sustainment requirements (Operational Success, Mean Time Between Operational Aborts, Operational Availability, etc.). This can be worked and levied against all levels of the design and at any desired point during design development as the assessments should be retrieved upon demand as “outputs” from the captured diagnostic design(s).

Determining the Diagnostic Integrity of the Design

The Diagnostic Integrity of the design is the determination of the maximum diagnostic capabilities, and any related constraints learned from the assessing of the Fault Detection and Fault Isolation expectations of the design in any operational or deployed paradigm. Typically, expressed as “FD/FI”, or “FDI”, as an integral component of a Testability Assessment, expose the strengths and weaknesses of the diagnostic capability of the design sufficiently early during design development lifecycle that any feedback from the “Testability Analysis” can better influence the design for a more cost effective sustainment lifecycle.

Without the ability to determine the diagnostic integrity of the design, “all” other design assessments products (including FMECA’s, FTA’s, System Safety Event Trees, etc.) and “Predictive Maintenance” technologies, assume that the diagnostic integrity of the fielded product is a given. Unfortunately, such assessments and Predictive Maintenance technologies fail to represent what they don’t know. In other words, critical assessment products and Maintenance technologies that target System Safety requirements may produce assessments that identify the likelihood of experiencing an Undesired Event but entirely without the knowledge that any such event(s) is/are able to be detected and unambiguously and Uniquely isolated!

Presumptions Inherent to Predictive Maintenance Technologies

Predictive Maintenance technologies are developed as independent endeavors. In theory, this produces an ability to observe and monitor very low-level failure conditions with precision using a variety of sensors specifically designed in companion with the elements of the design targeted by the condition-based technologies. However, these specifically targeted elements within the design that benefit from the implementation of Predictive Maintenance technologies, are ultimately only individual “actors” within the much broader integrated system. As such, the Predictive Maintenance effectiveness is subservient to the inherent diagnostic constraints of the overarching integrated systems’ design.

The limitations of the effectiveness of any maintenance philosophy, including Predictive Maintenance, is determined by the diagnostic integrity of the full “Integrated System”, or the fielded asset. The interdependencies of the failures and functions throughout the entire integrated design own an integral role in setting the boundaries for the diagnostic integrity of the fielded asset. This is the primary impetus behind not only performing design assessments early during design development, but with a diligent approach, like ISDD, that masterfully exposes the weak areas of traditional diagnostic design that manifest covertly during the integration of other subsystems within the design.

When considering the acceptance of any System Safety Assessment products, or prior to investing into any Predictive Maintenance application, please become familiar with the critical role and choice of establishing Diagnostic Certainty throughout the entire complex or critical system. Significant success can be achieved in the regard by determining if the Faults are Uniquely Isolated (FUI). That is, are the failed function(s) able to be discerned from any other non-failed function(s) with any dissimilar severity. Fortunately, such assessment products available for the eXpress model contain the necessary diagnostic savvy to make this distinction and fully integrate this knowledge across the entire System design for assessment and sustainment activities throughout the entire product lifecycle.

Related Links:

Risk Associated With Sub-Optimal Design

BIT Optimization – Validation- Integration

Facilitating all levels of Design Architecture